How to ensure that the structural design of the bottom of the tank meets the requirements of high-load work?

Release Time : 2025-03-27

To ensure that the structural design of the bottom of the tank meets the requirements of high-load work, comprehensive consideration and optimization are required from multiple aspects.

1. Clarify the workload and requirements

First, it is necessary to clarify the specific requirements of the workload, pressure range, working environment, etc. that the bottom of the cylinder of the construction machinery needs to withstand. This includes understanding the extreme working conditions that the bottom of the cylinder may encounter during work, such as high temperature, high pressure, high impact, etc. By analyzing the work requirements in detail, accurate data support can be provided for the structural design of the bottom of the cylinder.

2. Select high-strength materials

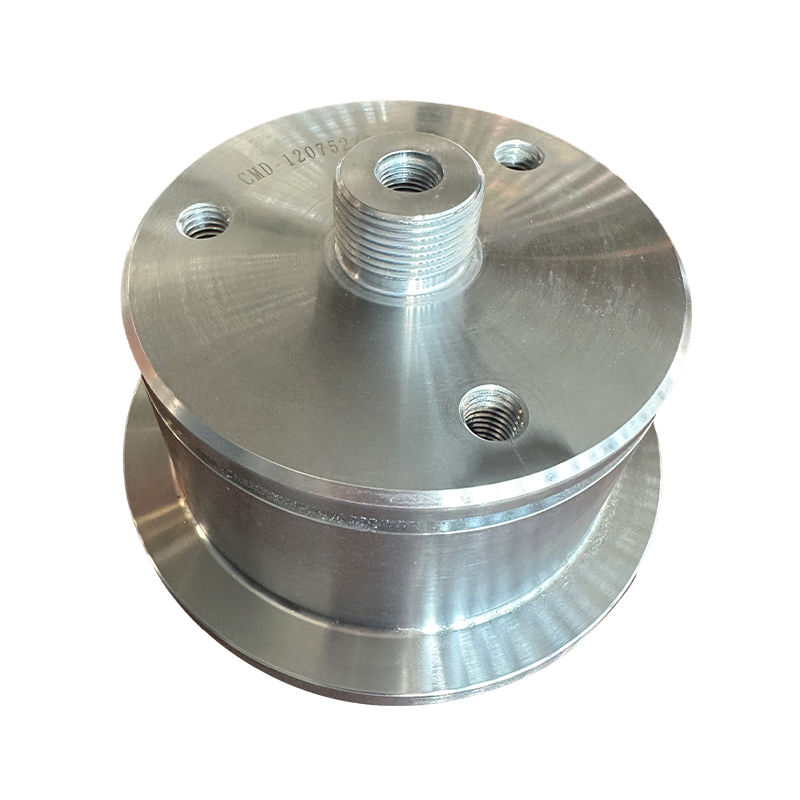

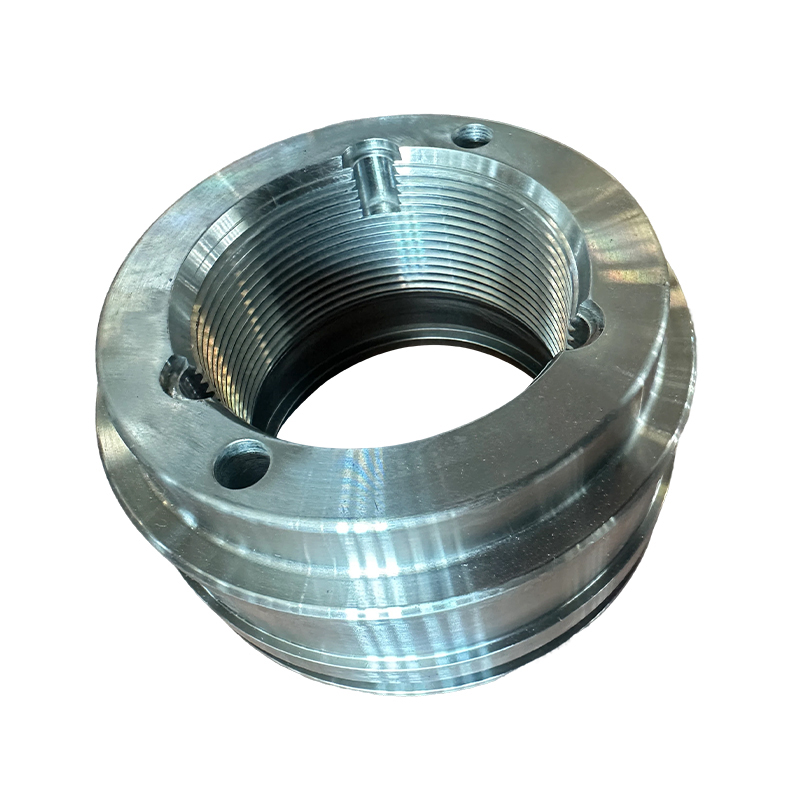

The material selection of the bottom of the cylinder is crucial to its load-bearing capacity. In a high-load working environment, materials with high strength, high toughness, good wear resistance and corrosion resistance should be selected. For example, high-strength alloy materials such as cast steel and forged steel are common choices. These materials can withstand greater pressure and impact while maintaining good stability and durability.

3. Optimize structural design

Thickness design: The thickness of the bottom of the cylinder should be reasonably designed according to the workload and the strength of the material. A thicker cylinder bottom can provide better load-bearing capacity and anti-deformation ability, but it will also increase cost and weight. Therefore, it is necessary to optimize the thickness design as much as possible to achieve lightweight while meeting the strength requirements.

Shape design: The shape design of the cylinder bottom should take into account the distribution and transmission of stress. Through reasonable shape design, stress concentration can be reduced and the bearing capacity of the cylinder bottom can be improved. For example, the shape design can be optimized by means of rounded corner transition and adding reinforcing ribs.

Connection design: The connection method between the cylinder bottom and the cylinder body is also the key to the structural design. Reliable connection methods such as bolt connection and welding should be adopted to ensure the close fit and stable operation of the cylinder bottom and the cylinder body. At the same time, the design of the connection part should also consider the convenience of installation and maintenance.

4. Strengthen manufacturing process control

The manufacturing process also has an important influence on the performance of the cylinder bottom. In the manufacturing process, key links such as material quality, processing accuracy and heat treatment process should be strictly controlled. By optimizing the manufacturing process, the strength and toughness of the cylinder bottom can be improved, and the generation of defects and cracks can be reduced.

5. Conduct strict testing and verification

After completing the structural design of the cylinder bottom, strict testing and verification should be carried out. This includes strength testing, fatigue testing, impact testing, etc. to evaluate the performance and reliability of the cylinder bottom under actual working conditions. Through testing and verification, potential problems can be discovered and improved to ensure that the cylinder bottom can meet the high-load working requirements.

6. Consider maintenance and care

Finally, the structural design of the cylinder bottom should also consider easy maintenance and care. For example, a structure that is easy to disassemble and inspect can be designed so that the cylinder bottom can be inspected and repaired regularly. At the same time, wear-resistant and corrosion-resistant materials or coatings can also be considered to extend the service life of the cylinder bottom.

In summary, ensuring that the structural design of the bottom of the tank meets the high-load working requirements requires comprehensive consideration and optimization from multiple aspects such as material selection, structural design, manufacturing process control, testing and verification, and maintenance and care. By taking these measures, the bearing capacity, stability and durability of the cylinder bottom can be significantly improved, thereby meeting the use needs of construction machinery in a high-load working environment.

1. Clarify the workload and requirements

First, it is necessary to clarify the specific requirements of the workload, pressure range, working environment, etc. that the bottom of the cylinder of the construction machinery needs to withstand. This includes understanding the extreme working conditions that the bottom of the cylinder may encounter during work, such as high temperature, high pressure, high impact, etc. By analyzing the work requirements in detail, accurate data support can be provided for the structural design of the bottom of the cylinder.

2. Select high-strength materials

The material selection of the bottom of the cylinder is crucial to its load-bearing capacity. In a high-load working environment, materials with high strength, high toughness, good wear resistance and corrosion resistance should be selected. For example, high-strength alloy materials such as cast steel and forged steel are common choices. These materials can withstand greater pressure and impact while maintaining good stability and durability.

3. Optimize structural design

Thickness design: The thickness of the bottom of the cylinder should be reasonably designed according to the workload and the strength of the material. A thicker cylinder bottom can provide better load-bearing capacity and anti-deformation ability, but it will also increase cost and weight. Therefore, it is necessary to optimize the thickness design as much as possible to achieve lightweight while meeting the strength requirements.

Shape design: The shape design of the cylinder bottom should take into account the distribution and transmission of stress. Through reasonable shape design, stress concentration can be reduced and the bearing capacity of the cylinder bottom can be improved. For example, the shape design can be optimized by means of rounded corner transition and adding reinforcing ribs.

Connection design: The connection method between the cylinder bottom and the cylinder body is also the key to the structural design. Reliable connection methods such as bolt connection and welding should be adopted to ensure the close fit and stable operation of the cylinder bottom and the cylinder body. At the same time, the design of the connection part should also consider the convenience of installation and maintenance.

4. Strengthen manufacturing process control

The manufacturing process also has an important influence on the performance of the cylinder bottom. In the manufacturing process, key links such as material quality, processing accuracy and heat treatment process should be strictly controlled. By optimizing the manufacturing process, the strength and toughness of the cylinder bottom can be improved, and the generation of defects and cracks can be reduced.

5. Conduct strict testing and verification

After completing the structural design of the cylinder bottom, strict testing and verification should be carried out. This includes strength testing, fatigue testing, impact testing, etc. to evaluate the performance and reliability of the cylinder bottom under actual working conditions. Through testing and verification, potential problems can be discovered and improved to ensure that the cylinder bottom can meet the high-load working requirements.

6. Consider maintenance and care

Finally, the structural design of the cylinder bottom should also consider easy maintenance and care. For example, a structure that is easy to disassemble and inspect can be designed so that the cylinder bottom can be inspected and repaired regularly. At the same time, wear-resistant and corrosion-resistant materials or coatings can also be considered to extend the service life of the cylinder bottom.

In summary, ensuring that the structural design of the bottom of the tank meets the high-load working requirements requires comprehensive consideration and optimization from multiple aspects such as material selection, structural design, manufacturing process control, testing and verification, and maintenance and care. By taking these measures, the bearing capacity, stability and durability of the cylinder bottom can be significantly improved, thereby meeting the use needs of construction machinery in a high-load working environment.